Produce Traceability Initiative (PTI)

1. GS1 Company Prefix: A globally unique identifier assigned to a company, typically 6-10 digits.

2. Item Reference Number: A variable-length code used by the company to identify the specific product.

3. Check Digit: A single digit calculated to validate the integrity of the GTIN.

Product Identification:

Lot association:

GTINs are paired with lot numbers to identify specific batches or crops. This adds another layer of traceability.

Barcode Encoding:

GTIN along with other data points such as lot number and packing date. It is encoded as a machine-readable barcode. (generally a GS1-128 or QR code).

Information Sharing:

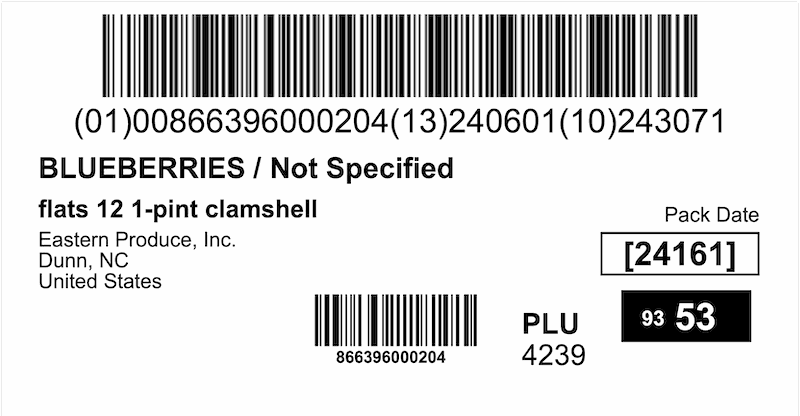

2. Barcode: Encodes the GTIN and additional data for quick scanning and processing.

3. Supplementary Information: Optional data such as harvest date or country of origin for enhanced traceability.

1. GTIN Generation: Reserva allows users to generate GTINs according to GS1 standards. This process can be automated for large-scale operations or customized for specific needs.

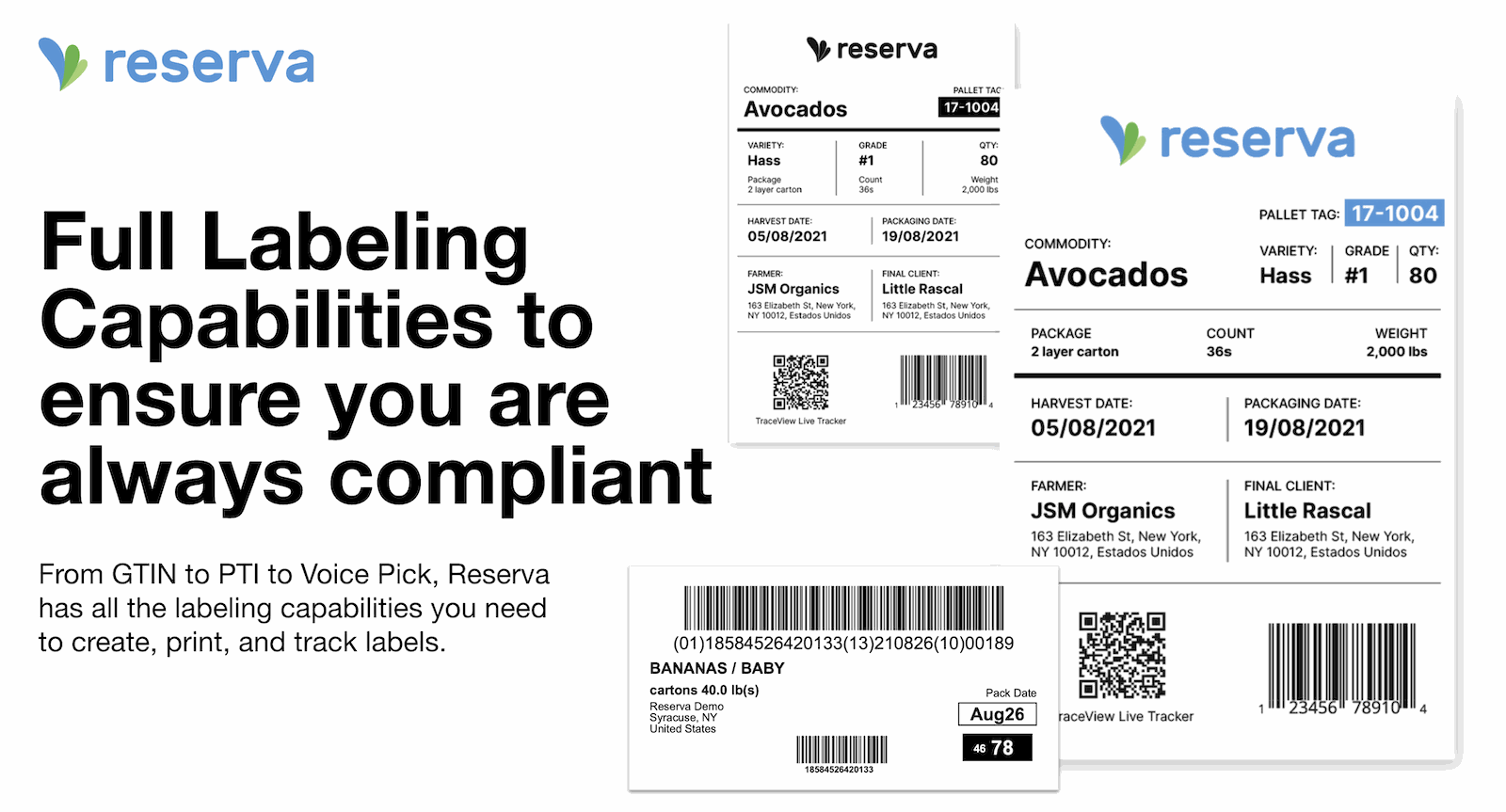

2. PTI-Compliant Label Printing: The system supports printing labels that include GTINs, lot numbers, and other required details directly from the platform. This ensures compliance while streamlining workflows.

3. Advanced Lot Tracking: Reserva’s inventory management system tracks products by lot, capturing all movements, from grading and repacking to shipping, ensuring end-to-end visibility.

4. Barcode Scanning: With mobile-friendly barcode scanning, Reserva enables real-time data capture at every stage of the supply chain, ensuring accuracy and reducing manual errors.

5. Data Integration and Reporting: Reserva seamlessly shares GTIN and lot information with trading partners via reports or integrations, enabling collaborative traceability.

6. Customizable Workflows: Businesses can tailor Reserva’s GTIN and traceability features to meet specific customer or regulatory requirements, enhancing flexibility.

GTIN and PTI-compliant processes are essential for produce businesses because they provide a standardized framework that ensures seamless communication and traceability across the supply chain. By using GTIN, all stakeholders can rely on a common language for produce barcoding, which eliminates confusion and improves operational efficiency. The ability to scan GTIN-enabled barcodes significantly reduces manual entry errors and accelerates key processes like receiving, inventory management, and shipping. Moreover, the enhanced traceability offered by GTIN allows businesses to quickly pinpoint affected products in the event of a recall or food safety issue, safeguarding consumer trust and ensuring compliance with regulatory standards. Together, GTIN and PTI allow produce businesses to meet modern food safety demands while optimizing their operational workflows. In short:

1. Global Standardization: GTIN ensures that all supply chain stakeholders use a common framework for product identification.

2. Operational Efficiency: Scanning GTIN-enabled barcodes reduces manual entry errors and accelerates processes like receiving and shipping.

3. Enhanced Food Safety: Rapid access to traceability data enables businesses to respond to recalls or safety issues swiftly.

4. Regulatory Compliance: GTIN ensures businesses meet PTI and other food safety standards, reducing risk and enhancing consumer trust.

By embedding GTIN and PTI support into its platform, Reserva ERP delivers a complete traceability solution tailored for the fresh produce industry. Its tools for GTIN generation, PTI-compliant label printing, lot tracking, and barcode scanning are designed to simplify compliance while improving operational efficiency. Combined with Reserva’s customer-led development process, businesses can trust that the platform evolves to meet their needs. With over 600 modules developed in response to real-world challenges, Reserva likely already has the solution for your specific traceability needs.

Choose a vibrant image and write an inspiring paragraph about it. It does not have to be long, but it should reinforce your image.

Request a Demo

Let us help you with your labeling requirements. Request a Demo